Harnessing tieback engineering techniques to accelerate production

Ben Cannell, Innovation Director at Aquaterra Energy

The perfect storm of an energy security crisis, surging inflation, and a challenging investment climate for fossil fuels has increased pressure on the oil and gas industry to find efficient paths to new production. While the expansion of renewable energy is good news, fossil fuels will still be required in the medium to short-term to support the transition to a cleaner energy system. The UK government therefore wants to accelerate production from the North Sea to fill the void created by Russian import sanctions. Tieback engineering represents a well-known but under-utilised engineering approach which could drive a sea-change in production efficiency.

Challenges with production

The oil and gas industry often remains wedded to a ‘waterfall’ project management model. This means that every stage, from platform manufacturing to drilling, happens sequentially, making for cumbersome and inefficient timelines to ultimately bring production online.

Processes have previously been substantially expedited by pre-drilling wells during the platform construction phase. This means they could then be tied back to the platform later in the project, and put onto production within days after the platform is installed. This approach is known as tieback engineering and was once common practice, before falling out of favour in recent years.

What caused its waning popularity?

Tieback engineering has been increasingly overlooked due to the advent and availability of cheap money, reducing the necessity for a speedy return on investment. Project risks have also increased in recent years with several examples of pre-drilled wells never being successfully tied back due to technical issues and a lack of tieback engineering continuity throughout a project’s lifecycle. The negative impact of suppliers and organisational departments expertly delivering their own elements of a project in isolation should not be underestimated. Without a tieback engineering function providing continuity between seemingly unrelated stakeholders, the project runs the risk of failure being baked into the design from the beginning.

Why tieback?

Tieback engineering from past projects has demonstrated the ability to achieve faster and lower cost routes to first production. By utilising specialist tieback engineering expertise, wells can be pre-drilled and suspended, all while the jacket and topsides are being built – this means that production can begin days after installation – shaving months if not years off production timelines.

Project management specialists can oversee collaboration and compromise among separate suppliers and organisational departments. By communicating, measuring, and managing success, this makes sure that a successful tieback is incorporated into designs.

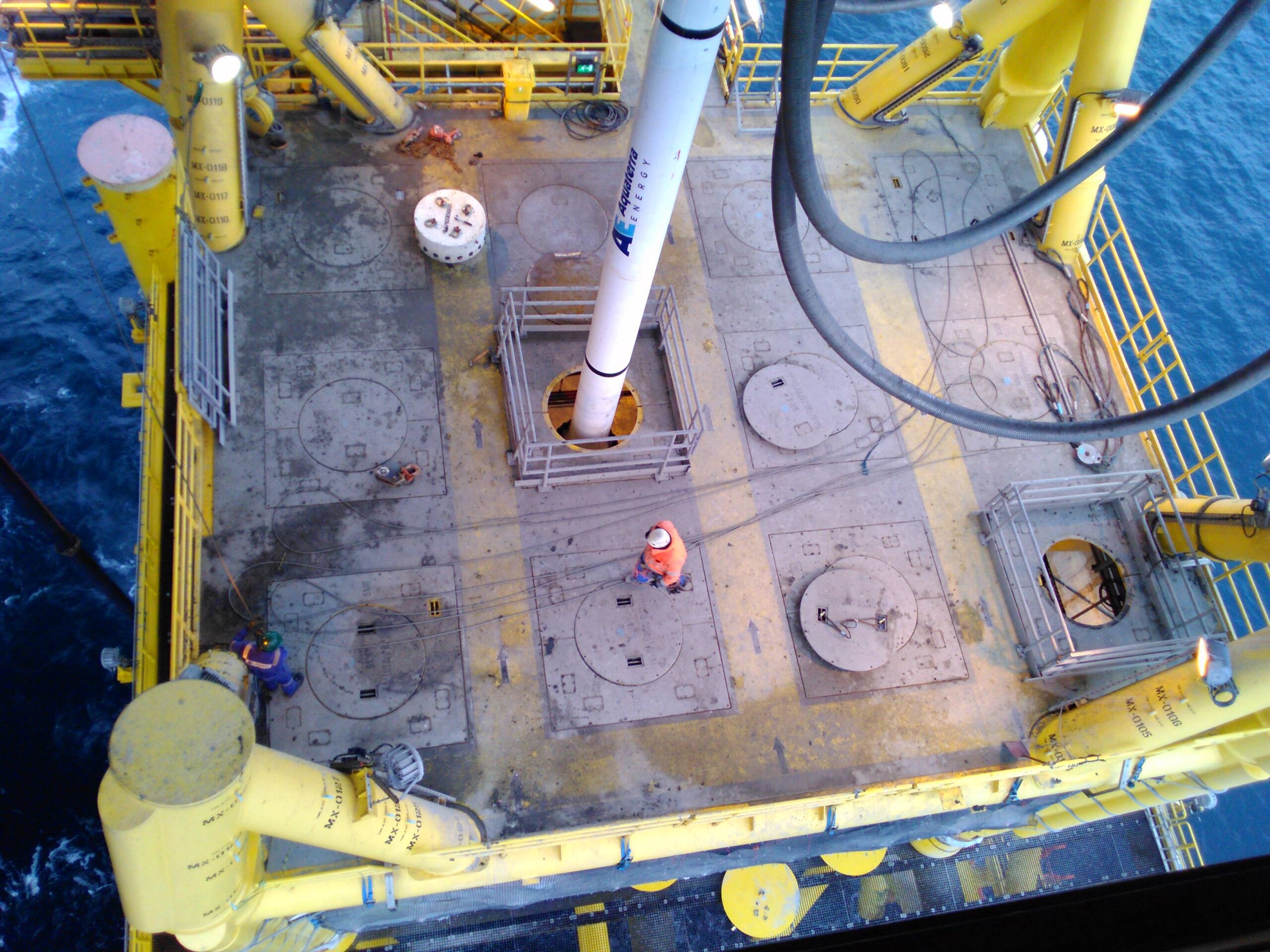

As an example, at Aquaterra Energy, we supported one energy giant to pre-drill, suspend and tieback six wells while the jacket and topside were still under construction. This enabled the operator to start production within days of the platform being installed, accelerating first oil and transforming the economics of the project.

Moving toward contemporaneous and collaborative production

At the root of all these innovations is the need to move from siloed and sequential production methods. Tieback engineering allows the industry to move beyond the waterfall approach, towards a model where platform construction, pre-drilling and tieback happen concurrently, removing several years off average production timelines.

Amidst an energy security crisis and an increasingly challenging investment climate for fossil fuels, there are growing financial and political imperatives for earlier and more cost-efficient routes to new production. Tieback engineering techniques offer the industry the opportunity to dramatically reduce cost and timelines.

Discover more about our tieback engineering expertise.