Offshore analysis helps KNOC optimise deep-water drilling project

Background

Aquaterra Energy was engaged by KNOC to conduct a comprehensive analysis for a deep-water drilling project in the East Sea, offshore South Korea. The project involved a deep water well at a depth of 1,233 meters from a drill ship.

KNOC had several key objectives for the analysis:

- Determine the maximum allowable environmental conditions and operational limits for the planned drilling system.

- Evaluate two different well design options – one with a supplementary conductor and one without.

- Identify the minimum fatigue properties required for critical components like conductor pipe connectors.

Solution

Aquaterra Energy’s team of experts performed a detailed analysis to address KNOC’s requirements. This included:

- Conducting sensitivity studies on the alternative well design options, cement levels, and pipe connector properties.

- Determining that the supplementary conductor design was necessary to ensure the system did not exceed code limits, specifically referencing API RP 16Q, API RP 2A-WSD and DNV RP C203 standards.

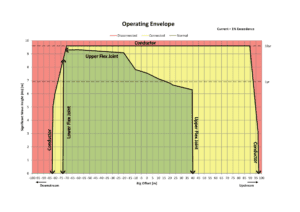

- Calculating the operating window for the drilling operation under drilling, connected and disconnected drilling phases as per API RP 16Q and AP RP 2A-WSD.

- Carrying out additional sensitivities to determine the maximum allowable cemental shortfall for the conductor system.

The calculated operating envelope highlighting the operating window in which drilling operations can be carried out safely.

Results

The comprehensive analysis provided KNOC with clear guidance on the optimal well design and critical component requirements for the deep-water drilling project. Key outcomes included:

- Recommendation of the well design with the supplementary conductor to meet safety and code compliance.

- Establishment of benchmarks for procurement of pipe connectors and other components, simplifying the planning process.

- Determination of the operational windows and limits for the drilling system, enhancing safety.

- Calculating the minimum acceptable conductor cement shortfall to aid in removing operation risks in the event the planned cementing operation could not be completed.

- Helped the client to understand that cementing to mudline is not required and drilling operations can continue rather than trying to mitigate a cement shortfall, saving rig time.

- Streamlining of the overall engineering planning, leading to time and cost savings in the pre-drilling phase.

By working closely with KNOC and conducting a thorough technical evaluation, Aquaterra Energy was able to deliver a solution that addressed all of the client’s requirements and provided a solid foundation for the safe and efficient execution of the deep-water drilling operation.

Testimonial:

“Aquaterra Energy’s detailed semi-sub analysis was invaluable during the planning phase of our offshore project. Their recommendations on minimum component capacities streamlined equipment procurement, while their thorough evaluation of multiple system designs ensured an efficient and reliable drilling system. We highly recommend Aquaterra Energy as a trusted partner for offshore analysis; their expertise added significant value during this crucial stage of planning.”

Sangho Kim, Drilling Engineer at KNOC