Delivering a jacket supported platform in a seismic region in the Gulf of Suez

Location: Egypt

Platform Design: Jacket Supported Platform

Key Features:

- 23m water depth

- 4 leg (complete with 2 inner conductors) jacketed platform

- 6m x 6m well configuration

- 4 of 30” conductors through legs with 2 additional central conductors

- 4 of skirt piles on jacket

- Access via helideck or boat transfer

- Well stream exported to central platform by 10” pipeline

- Local power generation with excess capacity to support existing satellite platform

Background

Aquaterra Energy was tasked to deliver a platform in a seismic region. The original scope was for the platform to be supported by four conductors; however, final geotechnical data showed the soil was significantly weaker than the preliminary data suggested. This meant additional pile supports would be needed to withstand the seismic load in the area.

The final platform design would to be suitable for installation by the already in-country heavy left vessel and suitable for fabrication in small module packages, to allow road transport by trucks to the new regenerated construction site for final assembly, and loadout at the quayside.

The topside equipment consisting of gas lift, water injection wellhead control panel, chemical injection unit and Nav Aids etc. would be operated from local generation, consisting of two diesel generators, one providing emergency back-up. At the time of engineering, there was further requirement to upgrade an existing production platform to increase production.

Solution

The platform design was changed moving away from a CSP to a jacket style structure which would overcome the soil conditions. The jacket design was based around the original CSP substructure and well spacing with the additional pile sleeves and steelwork added. This approach allowed the design of the topsides to continue without interruption, as the locations of the interface to the jacket and key topsides equipment remained unchanged.

The platform jacket and topsides were engineered to fabricated in modules in Alexandria and transported to Zeit Bay on the Gulf of Suez for final fabrication which ensured local content was maximised. All modules were able to be installed from the heavy lift vessel which, had already been sourced locally. The topsides incorporated a helideck, along with a small accommodation module for emergency purposes, power generation and a test separator. A bridge link was made to gain access to the existing production platform and link the two platforms together.

Our Aquaterra Energy team were on-site throughout the project to oversee fabrication and pre-commissioning, prior to loadout and offshore installation.

Results

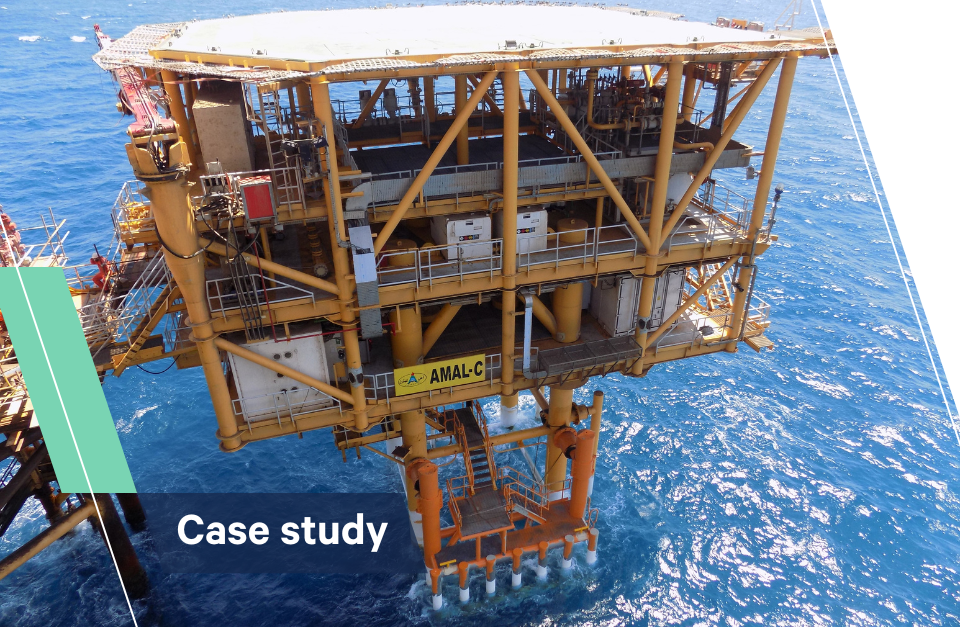

We successfully and safely designed, fabricated, and installed the AMAL-C platform for a seismically active location in the Gulf of Suez.

The platform was fabricated in modules and transported using trucks to a reconstructed fabrication facilities that had been closed for several years. This method dramatically reduced the costs of the platform, whilst maximising the local content capacity of each facility.

During the engineering process the need to increase the structural performance and increase the CSP to an innovative jacket structure design was completed to suit the location.

In conjunction with the drilling activities the production platform of AMAL-B was upgraded adding an additional 90Te of piping to increase the production flow rate. A joining bridge-link was placed to allow easy access between the two platforms.

Download our Sea Swift: Key projects and experience book

For more information on our offshore platform delivery expertise