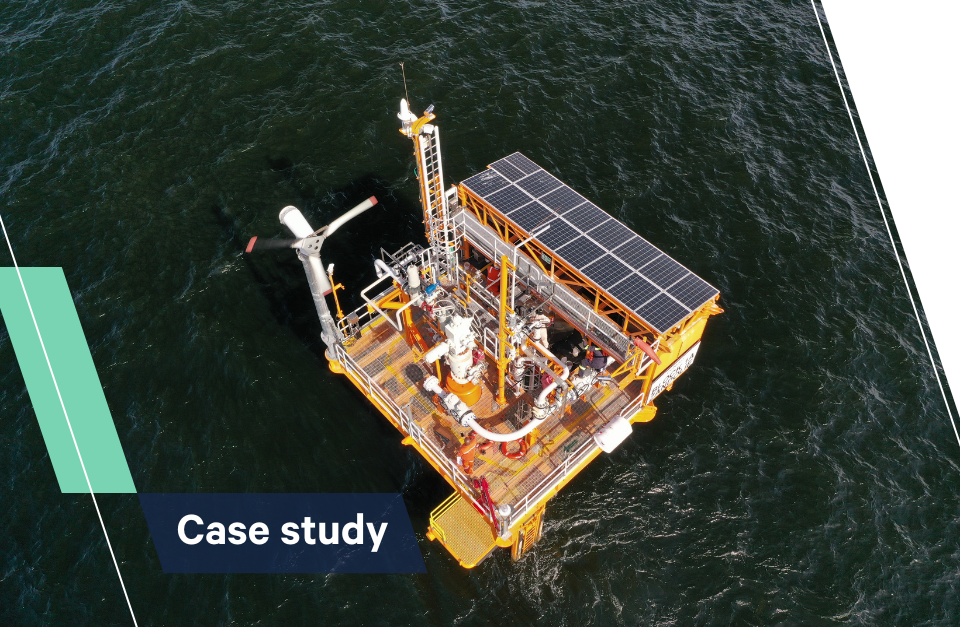

First of its kind 100% renewably powered platform in Trinidad and Tobago

Location: Trinidad and Tobago

Platform Design: Braced Monopile Platform

Key Features:

- 20m water depth

- Single well platform

- Powered by wind and solar energy

- Designed to withstand seismic loads

- Intelligent monitoring systems

Background

Following the success of a previous platform with the same operator, Aquaterra Energy were approached with the challenge of delivering rapid returns and reduced CAPEX and OPEX while simultaneously reducing carbon emissions across the project lifecycle. We were also tasked with creating a minimum facility platform that was 100% powered by renewable energy, in a region with highly changeable weather conditions that added additional challenges around energy intermittency risks.

The team also had to contend with the conflicting requirements of having a platform in 20 metres of water in an area with very high-seismic loads, while also minimising the carbon-intensive steel used in the platform. The project was completed in 31 months, amidst the Covid-19 pandemic.

Solution

The platform was designed to use a combination of Wind and Solar power, alongside four days of additional power capacity via batteries. This eliminated the need for traditional diesel generators or cables connecting to the grid for power.

Aquaterra Energy’s engineers harnessed a novel steel bracing support structure with legs locking monopiles together to withstand seismic activity. Removing the need for a huge carbon-intensive steel platform on the seabed.

Results

The project’s modular design meant it could be 100% fabricated in-country and that it could be transported in prefabricated parts and assembled on-site. It was installed using the already in-country, jack-up rig.

Intelligent monitoring and predictive maintenance allow the platform to operate 100% unmanned and a reduction on average maintenance visits. A pipeline to the nearby Iguana field enables the platform to share processing facilities with the existing Iguana Platform.

ESG stats:

- 100% renewably powered

- 100% fabricated in-country

- Generated approximately 371 local jobs

- Generated 476,613 employment hours

- Delivered with 56.4% local content spend

- Utilising existing in-country infrastructure for installation – creating savings on transport emissions

- Monopile design created a reduction in steel requirements

Download our Sea Swift: Key projects and experience book

For more information on our offshore platform delivery expertise