Delivering a 100% autonomously powered Sea Swift platform

Location: Angola

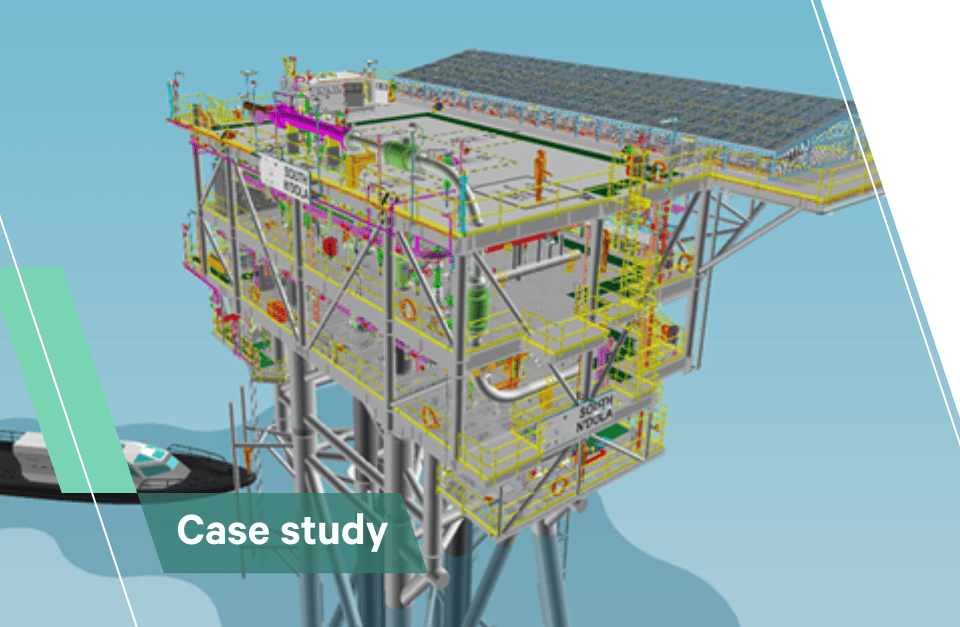

Product: Jacket-Supported, Sea Swift offshore platform

Background

As part of a multi-platform contract, Aquaterra Energy were tasked to design a jacket-supported Sea Swift platform for a supermajor, located offshore Angola.

The Integrated Basis of Design required the platform to be completely autonomous from a power generation and storage perspective. This was due to its distance from the host platform, which negated the ability to run a subsea cable, as well as a desire from the client to reduce the safety risks associated with personnel travelling offshore for maintenance visits.

Solution

Working closely with the client, the selected solution was a power system using PV panels with battery storage for

back-up power.

The design of the solar power system has platform wide implications for all other systems, due to voltage and power consumption restrictions. This involves a multi-disciplined approach to platform design to ensure alignment, for example, all disciplines needed to review their individual power requirements to ensure that a 3KW maximum was not exceeded.

By working closely with solar panel specialists, we calculated the optimal number of panels that would be needed for 100% autonomous power. It was identified that North facing solar PV panels would give maximum power generation, and any possibility of shading was eliminated by ensuring that any large structures were not positioned in front of any PV panels.

A Best Available Technology (BAT) assessment was undertaken within the detailed design phase to ensure that the solar package was fit for purpose, and the harvesting of solar energy was optimised during hours of power generation.

Due to power consumption restrictions, we also implemented additional power-saving innovations to support this approach, for example:

- The use of 24V DC equipment only

- Use of PV panels with bypass diodes

- Use of LED linear lighting with lesser power demand compared to conventional types

- Lighting on the platform is only active when attended which reduced operating hours and less change out of components

- Load shedding of non-critical loads to reduce peak load demand during night times

- Remote battery monitoring and status reporting

- Fully zone rated system, so power can always be on for critical production and safety critical loads

Results

By implementing a power system that used PV panels with battery storage for back-up power, we were successful in designing a 100% autonomously powered platform using solar energy. The net gains from this approach, compared with a traditionally diesel-powered facility are:

- No Green House Gas emissions for electricity generation

- 100% of produced fossil fuels can go to customers

- Reduction in opex and capex

- Removed requirement for re-fuelling visits, creating a reduction in offshore personnel visits

Download our Sea Swift: Key projects and experience book

For more information on our offshore platform delivery expertise