The evolution of offshore platform design

By Stewart Maxwell, Technical Director at Aquaterra Energy

If someone from 2003 were transported to the present, they would hardly recognise the offshore landscape of 2023 and it’s safe to say that by 2043, the changes will be even more notable, as the pace of transformation continues to accelerate.

Driven by the balancing act between the imminent need for energy security whilst spearheading transition targets, in the last decade we have pivoted from being dominated by oil and gas to an emerging mix of offshore wind, carbon capture and green hydrogen production.

Offshore tools, technologies and engineering approaches have moved at a similar pace. As the most familiar piece of offshore infrastructure, it may not be immediately obvious how offshore platform design has been at the forefront of this transformation, but there has been a revolution in platforms in recent years.

The next generation of offshore platform design

Until not too long-ago oil and gas was the only offshore game in town. Today, large stretches of the coastal shelf have many wind turbines scattered across them. Tomorrow, we will add the likes of offshore green hydrogen production, CCS reinjection projects and the next generation of oil and gas infrastructure too.

In other words, an entire offshore economy is booming, and each project or technology will need an offshore platform design to stand on. Some of it may be floating, but the demand for fixed platforms will remain. With so many new approaches, the crucial question is: how to design with flexibility in mind?

Looking to the future

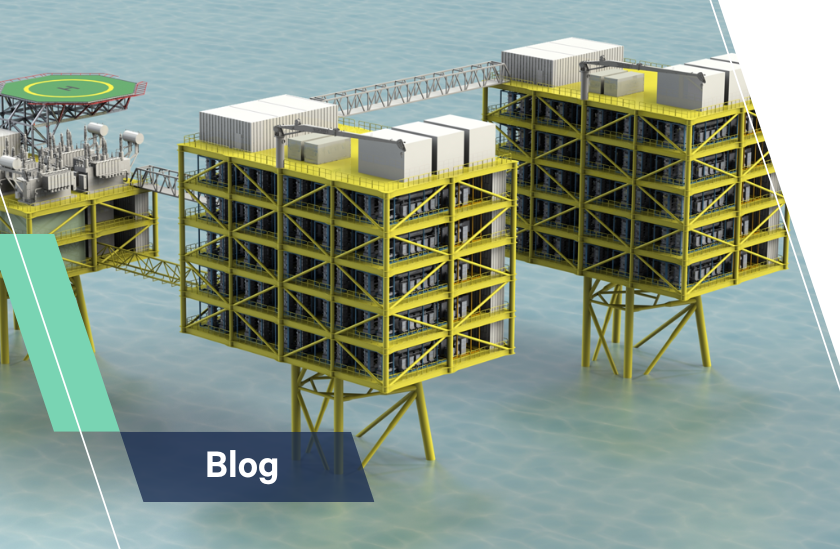

Broadly speaking, we can imagine two approaches to baking flexibility into offshore platform design. One is ‘bigger is better’, the other is to focus on modularisation, allowing offshore developers to ‘mix and match’ the right topsides with the right subsea structures.

While some projects may still necessitate full jacketed substructures due to topside requirements or soil conditions, many can benefit from simpler, lighter offshore platform design. Industry leaders recognise that smaller, modular platforms like our Sea Swift platforms are the future of offshore engineering.

Choosing tailored offshore platform design offers multiple advantages: reduced carbon emissions, cost savings in fabrication and transportation, lower operational expenses, and faster production times.

This flexibility can benefit CO2 injection projects too. Through merging new technologies with the modular approach mentioned earlier, platforms can serve as offshore wind substation substations, custom-sized for each project, transmitting power to onshore grids. Additionally, they can incorporate electrolysis technology for green hydrogen production, offering operational flexibility.

Taking things to the next level with advanced intelligent platforms

Operators committed to reducing their carbon footprint are exploring innovative ways to achieve decarbonised project execution. One approach involves reimagining topside power sources. Offshore platform design being adaptable, can seamlessly integrate renewable energy sources like solar panels or wind turbines, replacing or supplementing traditional diesel gensets, driving forward carbon savings.

Off the coast of Angola, we recently created a fully autonomous platform for a major operator. The remote location ruled out a subsea cable connection, and the client wanted to reduce safety risks associated with personnel travelling offshore for maintenance visits. Our solution featured PV panels and battery storage for complete autonomy, resulting in an efficient platform customised for the operation’s needs.

Intelligent platforms lead the energy transition, enabling today’s and tomorrow’s infrastructure. They reshape legacy assets, fostering a sustainable offshore economy. Intelligent engineering improves emerging energy sources and reduces emissions in all projects. Rapid, adaptable deployment is crucial.

Discover more about platforms here.