Offshore carbon capture and storage: past, present & future

Ben Cannell, Innovation Director at Aquaterra Energy

Estimated read time: 9mins

Blog summary:

With similarities and roots in enhanced oil recovery, carbon capture and storage (CCS) is viewed as a critical technology for meeting global net zero ambitions. In recent years, the industry has advanced at pace and now stands on the verge of a breakthrough.

While numerous technical challenges must be addressed, the oil and gas sector possess significant heritage expertise and technology that can play a crucial role in advancing CCS.

Ben Cannell explores how these can be applied to support offshore CCS in unlocking its full potential, plus paints a picture of what a large scale roll out will look like.

What is carbon capture and storage (CCS)?

According to the North Sea Transition Authority, “CCS refers to a variety of processes which capture and store carbon dioxide emissions, generally from industrial processes. The carbon dioxide can then be transported, including via repurposed gas pipelines, and stored, for example within storage reservoirs in the UK coastal shelf, including depleted oil and gas reservoirs and saline aquafers.”

A history of offshore carbon capture and storage

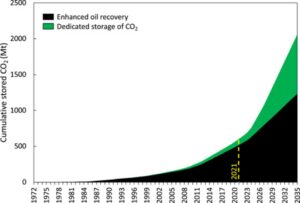

Despite being one of the global energy sector’s more recent breakthrough technologies, carbon capture and storage technology has a long history. Since the early 1970’s the practice of deploying CCS technology for enhanced oil recovery has been well recognised across the industry. However, some CCS technologies go back even further, with technology being deployed as early as 1920s to separate more valuable gases, such as methane, from CO2.

In those early days, the motivation behind capturing these gases was not environmental; however, the potential for CCS to reduce the impact of CO2 released into the atmosphere has become increasingly apparent. For example, projects in the 1990s and 2000s, such as the Sleipner CCS project and the IEA Weyburn Project, were amongst the first demonstrations which explored the potential of large-scale offshore CCS for environmental purposes.

Today, the global CCS industry has made major progress and is on the verge of a breakthrough. According to the Global CCS Institute, in 2020 there was about 40 million tons CO2 per year capacity of CCS in operation and 50 million tons per year in development, with offshore storage of captured CO2 being a key element of the future of the industry.

Martin-Roberts et al 2021. Historic and planned future (to 2035) partitioning of CCS. Licenses under CC BY 4.0

A crucial tool in lowering emissions

CCS has faced a range of criticisms, from questions of financial viability and delivery challenges, to being a sort of ‘get out of jail free’ card that enables large scale emitters to continue their operations as before. However, in the race to net zero, carbon capture and storage is not optional. To remain aligned with the IEA’s target indicator for its sustainable development scenario, 5,635 megatons of CO2 will need to be captured globally per year by 2050, more than total US CO2 emissions in 2022. For hard to abate static industrial emitters (especially where clustered together) such as cement and steel production through to power generation and chemical manufacture, CCS is the fastest way to significantly reduce these CO2 emissions, as alternatives are many years away from reality.

Due to a favourable geography in the North Sea with large saline aquafer formations and their close proximity to large hard to abate industrial emitters, it has also been identified as a key technology by the UK’s net zero strategy, with the government aiming to capture and store 20-30 million tonnes of CO2 in the North Sea per year by 2030 and over 50 million tonnes by 2035.

Delivering CCUS at scale

While the need is clear, a prevailing question in the industry has been how to address negative perceptions and successfully deliver CCS at the scale required to meet net zero ambitions. On the point of economics, the introduction of carbon pricing and emissions trading schemes is beginning to provide the incentives which will lead companies to opt for CCS rather than releasing carbon into the atmosphere.

To reach the scale needed, however, the industry must demonstrate that it can answer questions from the public around safety and reliability. Any sort of leakage during project delivery could have a disastrous effect on these perceptions, so licensing authorities in the UK require all CCS projects to have a robust monitoring plan as part of the licensing process. Ironically some of the reasons that make the UKCS such a good target for CCS projects (mature basin, with detailed information on the geology from years of oil and gas exploration and production), pose leakage risks for some target sites via previously abandoned legacy wells that were either entered, or pass through a prospective CO2 storage site.

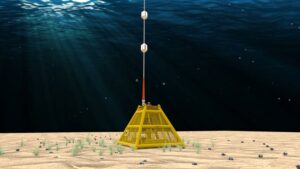

To meet this need, we have extended our well re-entry service to provide a means to locate and then safely re-abandon these legacy wells. And to address concerns around long-term site integrity for the offshore CCS industry and to ensure projects can proceed through to the licensing stages, we have developed and launched an innovative CCS monitoring, measurement and verification solution. The integrated system offers full life of field monitoring ensuring the risk of CO2 escape can be addressed instantly, avoiding major leaks.

CCS engineering poses some of its own unique challenges, such as high pressures, sweet corrosion and ultra-low temperatures. This means that standard low-alloy carbon steels deployed in oil and gas may not be suitable for CCS projects. To help tackle this, we developed a fully CCS ready riser and workover system, which will allow operators to safely perform workover and intervention operations in low temperature and high-pressure CCS subsea sites.

Redeploying CCS infrastructure

With deep roots in the oil and gas industry, there is huge potential for heritage engineering, expertise and equipment to be redeployed to support the sector as it is brought up to scale. At Aquaterra Energy, we recently secured a contract with INEOS, to support with the life extension and repurposing of an existing offshore platform for CO2 injection as part of the Project Greensand CCS development in the North Sea. Greensand is the most mature CO2 storage project in Demark, aiming to store up to 1.5 million tonnes of CO2 per year by 2025. This ground-breaking project is a key demonstrator of how the heritage oil and gas industry will be vital to support offshore CCS at scale.

The future of CCUS

The successful deployment of CCS is not only vital for negating the worst harms of carbon emissions but is also a valuable economic prospect for all stakeholders. In the not-too-distant future, we could see industrial emissions captured at a grand scale and efficiently transported and stored, not only reducing environmental footprints but also bolstering the long-term finances of companies by protecting against the potential for future increases in carbon taxes and schemes. The sector is on the verge of a breakthrough and trailblazing companies are now going through the steps needed to deliver CCS at scale.

At Aquaterra Energy, we see our role as redeploying our decades of heritage offshore experience and applying it to provide the consultative advice, engineering and technology which will enable it to reach the scale needed.

We offer a range of products and services to support CCS, including specific riser systems and analysis, pre-FEED and FEED studies, and complete decommissioning services and support.

Talk to a member of our team to learn how we can support you carbon capture and storage project.

Bibliography

Jinfeng Ma, Lin Li, Haofan Wang, Yi Du, Junjie Ma, Xiaoli Zhang, Zhenliang Wang. 2022. Carbon Capture and Storage: History and the Road Ahead,

https://www.sciencedirect.com/science/article/pii/S2095809922001357

Emma Martin-Roberts, Vivian Scott, Stephanie Flude, Gareth Johnson, R. Stuart Haszeldine, Stuart Gilfillan. 2021. Carbon capture and storage at the end of a lost decade.

https://www.sciencedirect.com/science/article/pii/S2590332221005418

National Security Technology Authority. n.d. Carbon Capture and Storage. https://www.nstauthority.co.uk/the-move-to-net-zero/carbon-capture-and-storage/

IEAGHG. n.d. Information Sheets for CCS. https://ieaghg.org/docs/General_Docs/Publications/Information_Sheets_for_CCS_2.pdf

International Energy Agency (IEA). 2023. CCUS in the Transition to Net-Zero Emissions. https://www.iea.org/reports/ccus-in-clean-energy-transitions/ccus-in-the-transition-to-net-zero-emissions

Global CCS Institute. 2021. Global Status of CCS Report. https://www.globalccsinstitute.com/wp-content/uploads/2021/03/Global-Status-of-CCS-Report-English.pdf

International Energy Agency (IEA). 2022 CO2 Emissions in 2022. https://www.iea.org/reports/co2-emissions-in-2022

Key takeaways:

In this piece we have answered:

What is offshore carbon capture and storage?

CCS refers to a variety of processes which capture and store carbon dioxide emissions, generally from industrial processes where the CO2 emissions are transported and stored including in depleted oil and gas reservoirs.

When did CCS first develop?

CCS developed at scale in the 1970s to support the oil and gas sector with enhanced oil recovery. Early CCS technologies were seen as early as the 1920’s but the industry’s current form began to take shape in the 1990s and early 2000s while significant progress has been made in recent years.

Why is CCS an important technology?

Carbon removals will be vital to ensuring that global net zero ambitions can be met. Without the large-scale deployment of storing captured CO2 emissions, the worst harms of climate change will not be avoided.

How can CCS be brought up to scale?

The oil and gas industry has a great deal of expertise which can be deployed to support CCS. From repurposing skills and expertise to developing technologies, it will play a vital role in the success of the sector.