Everything you need to know about our Sea Swift offshore platform

Blog summary:

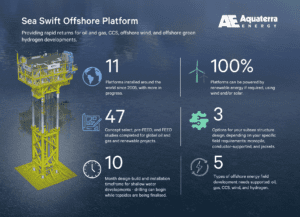

In this blog, Stewart Maxwell delves into the Sea Swift offshore platform, a flexible and efficient platform solution for the offshore energy sector, including oil and gas, CCS, hydrogen, and wind. It discusses key benefits including reducing construction times, capital expenditure, emissions, and time to initial production. The platform’s modular design permits bespoke structural configurations, with options such as Monopiles, Conductor Supported, and Jackets tailored to specific project requirements.

The blog highlights Sea Swift’s adaptability for various offshore energy requirements, including offshore wind capabilities, and applications in CCS and green hydrogen production, showcasing its significant role in the evolving energy landscape.

What is the Sea Swift offshore platform?

Sea Swift is our flagship platform offering for offshore energy operators. Designed to meet the evolving needs of the industry, it offers a flexible, intelligent platform solution that can be tailored to projects right across the offshore energy space, from oil and gas and carbon capture and storage (CCS), through to hydrogen generation and wind.

Sea Swift is trusted by operators all around the world. Designed with efficiency and flexibility as its driving principles, the platform minimises build and implementation times while reducing CAPEX, emissions and time to first production.

So, as a highly flexible solution, you may be wondering how Sea Swift can meet your own project needs? In the following piece, I have broken down the key benefits and applications of the platform.

Firstly, watch our video summary of the Sea Swift platform

Flexible, intelligent, modular

When writing for World Oil last year, I discussed that with no two offshore projects being the same, it makes sense that no two platforms should be either[1] . A key principle of Sea Swift is versatility, allowing offshore developers to ‘mix and match’ the right topsides and subsea structures for their own needs.

Some projects will still require a full jacketed substructure, but many can benefit from simpler, lighter offshore platform designs. When a platform solution is rightsized and tailored to closely fit project needs, advantages can range from reduced carbon emissions, cost savings in things like fabrication and transportation, to lower operational expenses, and importantly, faster production times.

For this reason, we designed our Sea Swift to come in a range of structural configurations, including:

- Monopiles

- Conductor Supported

- Jackets

Our adaptable design approach means that platforms can be fabricated and installed using in-country facilities anywhere, keeping expenditure and emissions low, while supporting expedited project timelines. Furthermore, this enables it to be installed via jack-up, or using other existing in-country infrastructure, along with a unique phased approach to the installation process that enables drilling to begin whilst topsides structures are being finalised – further enhancing the efficiency and faster returns on projects.

A visual guide to Sea Swift

Talking topsides

With a whole array of new offshore technologies coming online across CCS, offshore wind and hydrogen, the future applications of offshore platforms are much broader than just oil and gas.

To meet this challenge, the topsides of Sea Swift platforms can be tailored for a full range of offshore sectors, including offshore wind substations, green hydrogen production facilities, and CCS injection sites.

Our topside designs can:

- Be any weight on jackets, and up to 650te for Conductor Supported designs

- Be digitally enhanced with the latest offshore monitoring and automation technology

- Be 100% renewably powered

- Host CCS injection equipment

- House electrolysers for hydrogen production

100% renewably powered

As operators seek ways to reduce their carbon footprint while also managing the costs of running a platform, we have ensured that Sea Swift is ready to meet the needs of the energy transition through reimagining topside power sources.

For example, off the coast of Angola, we have designed a 100% autonomously powered platform for a major operator. We have also engineered a 100% renewably self-powered platform in Trinidad & Tobago, eliminating the need for traditional diesel generators or cables connecting to the grid. This renewably powered, autonomous approach represents the next generation of intelligent offshore platforms, enhancing the efficiency and minimising the carbon intensity of offshore operations in line with the demands of today’s industry.

The right choice for your oil and gas development

Sea Swift has been designed to enhance the returns of existing oil and gas projects and transform the economics of non-viable ones. Deploying the engineering methodology discussed above, we offer a low-risk, low-cost pathway to reduced time to first oil or gas while minimsing the carbon intensity of projects.

We place high value on increasing local content in the locations that we operate and look to work with local fabrication partners and source materials from in region wherever possible. A Sea Swift monopile or conductor supported platform design can be fully installed using a jack-up, or other existing in-country infrastructure, and our modular approach enables drilling operations to begin whilst topsides structures are finalised, greatly reducing the timeline to first production.

Ready for carbon injection

For CCS projects requiring a new platform installation, our Sea Swift CO2 platform solution is the ideal choice. Platform topsides can host CO2 compressors and storage infrastructure which has been designed to match the specific properties and behaviour of CO2. Depending on the number of wells you are planning to inject a monopile or jacket design could be utilised.

Coupled with our CO2 monitoring technology, Sea Swift offers a leading solution for CCS projects as the industry prepares for a major breakthrough.

Meeting the needs of offshore wind and green hydrogen

Sea Swift can also be deployed as a substation to efficiently transform and transmit power generated by offshore wind farms to onshore power grids. Available in a variety of sizes and configurations, it can be designed to cater to the specific requirements of your wind farm project – whether you need a large, multi-platform substation or a compact and lightweight solution for a smaller, marginal wind development.

Sea Swift also offers a pioneering solution for green hydrogen production from your offshore wind development by integrating electrolysis technology to efficiently split water molecules into hydrogen and oxygen to produce green hydrogen that meets the most rigorous industry standards.

It’s important to note that Sea Swift’s modular design enables scalability, allowing you to adapt and expand your green hydrogen production capacity as needed. Whether you start with a single unit or a large-scale deployment, this flexibility ensures efficient and cost-effective operations.

A turnkey platform delivery offering

Our global team of experts have delivered Sea Swift platforms all across the world. We provide a comprehensive engineering, procurement, construction, and installation service that covers everything from analysis to design, fabrication, project management, and offshore installation, whatever the needs of your project.

Speak to a member of our team to learn more about how our Sea Swift platforms can support your project.

Key takeaways:

What is our Sea Swift platform?

Sea Swift is a flexible and efficient offshore platform solution tailored for various sectors in the offshore energy space, including oil and gas, CCS, hydrogen and wind. It’s designed for minimised build times, reduced CAPEX, lower emissions, and faster production.

What are the advantages of deploying a Sea Swift platform?

The main advantages include reduced carbon emissions, cost savings in fabrication and transportation, lower operational expenses, faster production times, and the ability to be fabricated and installed using local facilities.

What sectors can Sea Swift be deployed across?

Sea Swift can be deployed across various sectors such as oil and gas, carbon capture and storage (CCS), offshore wind substations, and green hydrogen production.

Maxwell, S. (2023). Offshore technology: Platform design: Is the next generation of offshore platforms changing offshore energy? World Oil Magazine. Retrieved from https://www.worldoil.com/magazine/2023/december-2023/features/offshore-technology-platform-design-is-the-next-generation-of-offshore-platforms-changing-offshore-energy/